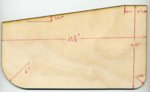

There are a great bunch of doors being made here, thanks to all who have shared, they have been an inspiration to me. I have attached a scan of a 1/4 scale model of a door a drew up in CAD and laser cut. I put dimensions on it. Eventually, I will have a couple cut out from Starboard, figuring they would last longer than plywood, and look better too. If anyone has any comments or thoughts on the dimensions in the photo, I would be pleased to hear them, and if they are of use to any of you, that's great too. I made the door part 1/8 inch shorter than the 32 inch opening for clearance.

View attachment 2923