- Joined

- Aug 26, 2018

- Messages

- 720

- Points

- 93

- Location

- DALLAS AREA

- Roxor #

- :-(

- Roxor Ownership

- No longer own

04/21/2022 UPDATE:

Today I finished up the rear flare hacking. I did some clean up and then re made the edge roll originally on the flare before I hacked on them. Oh my fake right thumb is killing me.

The way I do the edge forming is with a pair of lineman pliers as we call them. A pliers with a flat tip about 1/2" wide and a face that's flat back about 1/8. Then notches and then a wire cutter. I scribed out a 1/4 back from the edge of the flare then just through a bunch of clinching and releases side by side by side repeatedly. Oh my hand. Lolol.

So got the flares worked and cleaned up as far as I am for now. Did I mention hands hurt? Lololol.

Then I mounted 3 RAM 1" ball mounts for holders for my GPS, the engine management controller and a cell phone or whatever else is needed. Mounted them on the roll cage in front of the passenger.

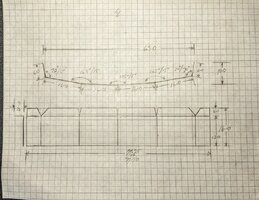

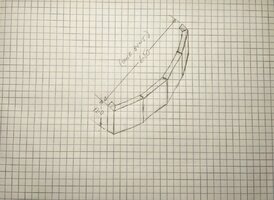

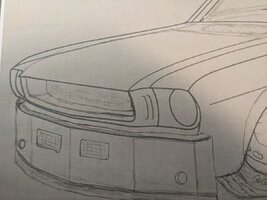

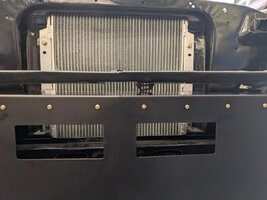

That's it for today. Tommarra I may tackle building front air dam structure using some old removed bumper supports that no longer fit since we have roll cage in the way. Lolol.

BDRAG

Today I finished up the rear flare hacking. I did some clean up and then re made the edge roll originally on the flare before I hacked on them. Oh my fake right thumb is killing me.

The way I do the edge forming is with a pair of lineman pliers as we call them. A pliers with a flat tip about 1/2" wide and a face that's flat back about 1/8. Then notches and then a wire cutter. I scribed out a 1/4 back from the edge of the flare then just through a bunch of clinching and releases side by side by side repeatedly. Oh my hand. Lolol.

So got the flares worked and cleaned up as far as I am for now. Did I mention hands hurt? Lololol.

Then I mounted 3 RAM 1" ball mounts for holders for my GPS, the engine management controller and a cell phone or whatever else is needed. Mounted them on the roll cage in front of the passenger.

That's it for today. Tommarra I may tackle building front air dam structure using some old removed bumper supports that no longer fit since we have roll cage in the way. Lolol.

BDRAG