02/20/2022 UPDATE:

Wow! Making great progress.

We made sure all the fuel lines from fuel tank to fuel pump were correctly tightened. Lines from fuel pump to firewall are good. Added 3 gallons of fuel to the 15 gallon tank. No leaks! Yippie!

Then we got the exhaust 100 % fit. Tacked it all together, located the area below the headers for the O2 sensor. Marked it. Located where the main exhaust hanger will be mounted. Then we removed the complete exhaust system as one unit.

Then I drilled out the pipe for the O2 sensors threaded bung is to go. Then Pete welded it all up. All together the complete exhaust system from the header collectors back only weighs about 30 pounds.

The headers were just in for fitting the exhaust with 4 of the 8 bolts. So while the exhaust was out we removed the headers then re installed them with the gaskets. WHAT A PAIN IN THE ARSS!

So to get the 4 bolts next to the inside radius where the header tube exits the 1/2" flange you have to drop the 4 bolts in, slap the gaskets on the bolts which just so happens have anti seize all over them since the bolts are stainless steel and the heads are aluminum. 1/4 turn here, then there, then drop the greasy bastard screw, start over. ERRRRRRRRR!

It took us about an hour to get the passenger side on. Then on the driver's side we had to bend and shape the dip stick tube around the headers and grind the tube mount flange that goes under one of the 4 dang hard to install bolts to fit. It sucked! But now the dip stick tube is installed and the headers are on the motor and will not be coming off again.

After the headers I grabbed the now one piece complete exhaust and slid it under the headers and then slid it back over a motorcycle strap hanging in the rear. Then raised the exhaust up to the collectors and bolted it in. Wow! That went GREAT! Works as we hoped it would! Lololol.

So that was my 5 hours of work for the day. Pete and I then sat and mulled over the *hit list and crossed off most of what's needed to start the thing up.

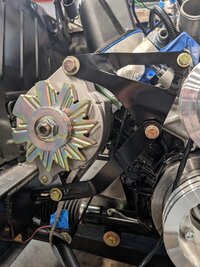

All that's left is for my darn on line ordered Optima battery get here, bolt on the water pump and thermostat housing, measure for the correct V - belt, install all the hardware 100% on the crank pulley and alternator. Re install the radiator and then get the correct hoses. The ones the forums say will work Don't!

Run a few wires, tie up loose wires. Test fire the fuel pump, bump the starter to see if it works when ya push the start button. Set the parameters on the EFI and all the MSD boxes. Test run the fan over ride switch just in case the MSD fan controller don't work.

Then dump some oil in after installing a filter, prime the the oil pump until oil flows through out the motor, install the distributor and rum the spark plug wires.

Then it's cross the fingers and hit the button.

More to come!!!

BDRAG