- Joined

- Jan 14, 2023

- Messages

- 24

- Points

- 13

- Location

- Gnadenhutten, Ohio 44629

- Roxor Ownership

- Roxor Owner

Just got my Roxor back from the dealer after 7+ weeks waiting for the correct parts. Sometime in January my grandson took the Roxor into a picked cornfield and proceeded to bury it in a really bad place where water drained off of a hill into a low area full of fine silt, corn stubble, and tall sawgrass. It was in the middle of a pouring rainstorm and to be honest he had never played around with machines that big in mud that soft. He was in up to the bottom of the body, but the Roxor never quit moving (completely stock). He eventually worked his way out and back to the shop a little shaken, because he admitted he wasn't sure he could walk out in mud up to his thighs. The machine was parked outside and the temp. dropped to low 20's and stayed there for a few days. The next morning the starter would spin but the bendix would not engage. Didn't take long to figure out that the starter had at least gotten wet and was frozen. Set up a windbreak and plugged in a space heater and the starter thawed out in about a half hour.

After we got it started found out the emergency brake cable had also frozen while engaged. Moved the heater to the back and thawed the cable out and released the brake. Made sure we didn't set the brake until the weather warmed up.

We were able to put probably 50-75 miles on the machine before we completely lost resistance in the clutch pedal, and the clutch seemed to be stuck partially engaged. The easiest thing to replace was the clutch slave cylinder, which seemed to be frozen. After the replacement slave cylinder froze in the same position,we took it to the dealer where the shop got a borescope in the bell housing. They found the clutch fouled with mud and vegetation which had wound around all the spinning pieces of the clutch and was holding the pressure plate away from the clutch. At this point, the shop dropped the transmission so they could clean out the bell housing and install the replacement parts.

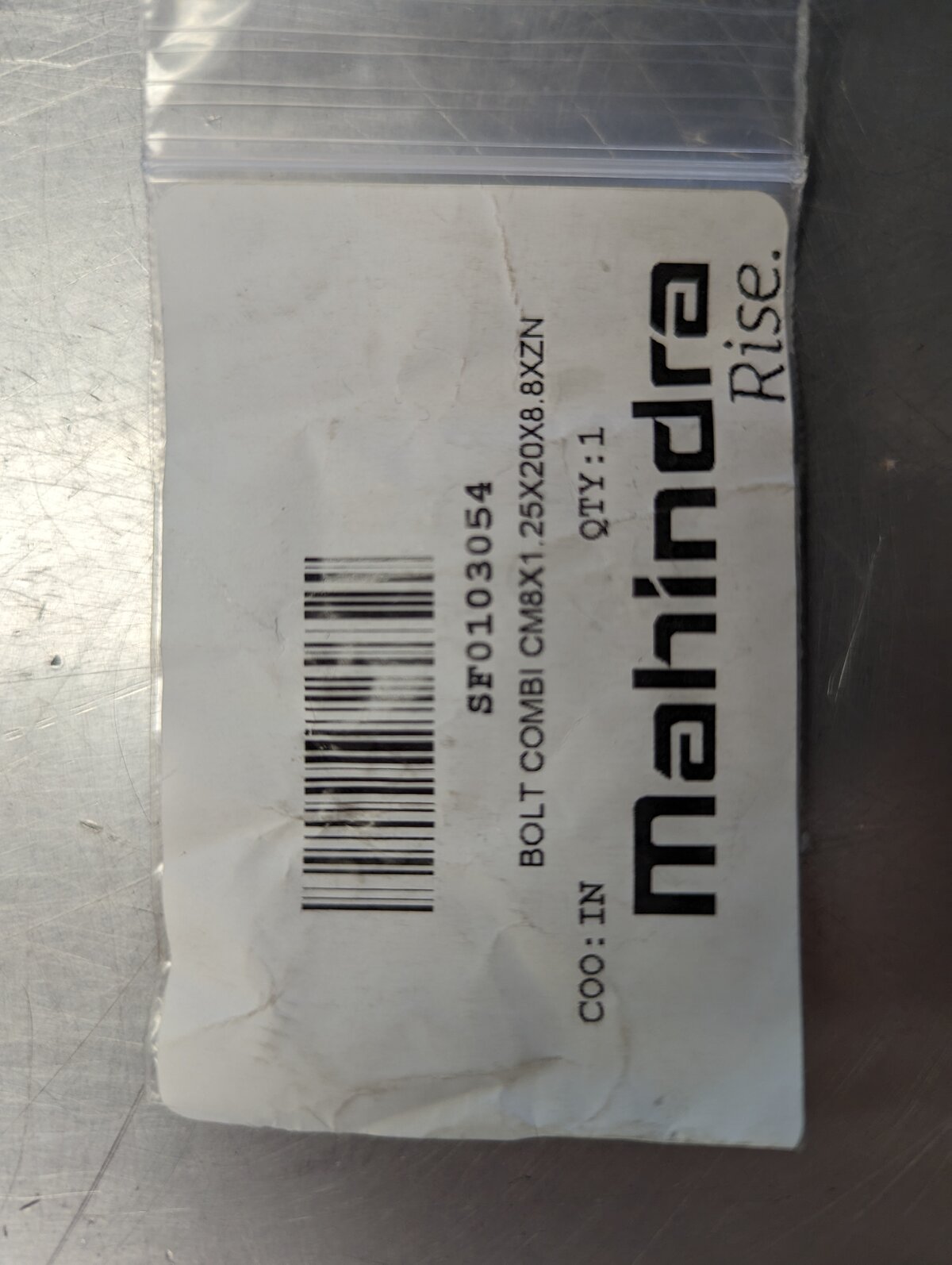

I have decided to collect a set of replacement parts that I think will need replaced in the course of a long productive life. I'll add that list at the end. I let the shop order parts through Mahindra Roxor and after a week of no info from Mahindra, I ordered the shop's list of parts from GI Store on Ebay. The sale was painless and the parts were promised in 2-3 weeks, depending on shipping and customs. Amazingly, the parts were delivered to my door in 7 days. I took them back to the shop (2 hrs. away) and waited. Found out in a few days that Mahindra had delivered their parts, and both Mahindra and Ebay had supplied the wrong 6 bolts the hold the clutch to the bell housing. These were special metric hex head bolts with an additional small knurled flange at the bottom edge of the bolt head. The diameter of the flange was critical due to clearance issues with revolving clutch parts. Between me and the shop we were able to locate three different bolts supplies that were similar, but not exact and they would not work. The shop finally found the bolt at Summit Racing with the correct dimensions, but the flange was missing the knurled edge that stood in place of a lock washer, for which there was no room. This was solved by a drop of red LockTite, and the shop was finally able to re-assemble and complete the rebuild. Hauled it home Thursday, and I've put 50 miles on it since. Really missed it while it was gone.

Final thoughts...according to the shop, they weren't sure how the mud and debris got into the clutch, but the long stringy vegetation wrapped around all the spinning parts was the kiss of death. Eventually jammed the 2 clutch pieces apart where everything froze. Beware of MUD and HIGH WEEDS. This has also magnified the parts supply chain disruptions, which I believe will only get worse. I've invested in a machine that I think will last a long time, but I know that certain components will eventually fail and may not be available. At the present time I have the funds and the parts seem to be readily available in India at the factory. I used to purchase, maintain and operate all the heavy equipment at the families sand and gravel mine. Mahindra parts seem reasonably priced compared to Cat. I've collected the following spare parts to put on the shelf.

(2) Clutch assemblies inc. throw out bearing, brass bushing and the hard to find bolts, See Mahindra part Number:

Clutch Master Cylinder

Clutch Slave Cylinder

Water Pump

Alternator, has a vacuum pump? on the other end. I've never seen anything like it and it will not be something to cross at NAPA.

Engine ECU stored in Faraday Bag.

Filters, belts.

Everyone that saw the damage was surprised that we were able to get that much mud and debris into the bell housing. I see videos of Roxors in deep flowing water, crawling over huge rocks, and they look fairly indestructible. They are not. I'm going to avoid taking it in deep anything if I can help it. I'm afraid it's only going to get harder to get it fixed. Hope someone finds this helpful.

After we got it started found out the emergency brake cable had also frozen while engaged. Moved the heater to the back and thawed the cable out and released the brake. Made sure we didn't set the brake until the weather warmed up.

We were able to put probably 50-75 miles on the machine before we completely lost resistance in the clutch pedal, and the clutch seemed to be stuck partially engaged. The easiest thing to replace was the clutch slave cylinder, which seemed to be frozen. After the replacement slave cylinder froze in the same position,we took it to the dealer where the shop got a borescope in the bell housing. They found the clutch fouled with mud and vegetation which had wound around all the spinning pieces of the clutch and was holding the pressure plate away from the clutch. At this point, the shop dropped the transmission so they could clean out the bell housing and install the replacement parts.

I have decided to collect a set of replacement parts that I think will need replaced in the course of a long productive life. I'll add that list at the end. I let the shop order parts through Mahindra Roxor and after a week of no info from Mahindra, I ordered the shop's list of parts from GI Store on Ebay. The sale was painless and the parts were promised in 2-3 weeks, depending on shipping and customs. Amazingly, the parts were delivered to my door in 7 days. I took them back to the shop (2 hrs. away) and waited. Found out in a few days that Mahindra had delivered their parts, and both Mahindra and Ebay had supplied the wrong 6 bolts the hold the clutch to the bell housing. These were special metric hex head bolts with an additional small knurled flange at the bottom edge of the bolt head. The diameter of the flange was critical due to clearance issues with revolving clutch parts. Between me and the shop we were able to locate three different bolts supplies that were similar, but not exact and they would not work. The shop finally found the bolt at Summit Racing with the correct dimensions, but the flange was missing the knurled edge that stood in place of a lock washer, for which there was no room. This was solved by a drop of red LockTite, and the shop was finally able to re-assemble and complete the rebuild. Hauled it home Thursday, and I've put 50 miles on it since. Really missed it while it was gone.

Final thoughts...according to the shop, they weren't sure how the mud and debris got into the clutch, but the long stringy vegetation wrapped around all the spinning parts was the kiss of death. Eventually jammed the 2 clutch pieces apart where everything froze. Beware of MUD and HIGH WEEDS. This has also magnified the parts supply chain disruptions, which I believe will only get worse. I've invested in a machine that I think will last a long time, but I know that certain components will eventually fail and may not be available. At the present time I have the funds and the parts seem to be readily available in India at the factory. I used to purchase, maintain and operate all the heavy equipment at the families sand and gravel mine. Mahindra parts seem reasonably priced compared to Cat. I've collected the following spare parts to put on the shelf.

(2) Clutch assemblies inc. throw out bearing, brass bushing and the hard to find bolts, See Mahindra part Number:

Clutch Master Cylinder

Clutch Slave Cylinder

Water Pump

Alternator, has a vacuum pump? on the other end. I've never seen anything like it and it will not be something to cross at NAPA.

Engine ECU stored in Faraday Bag.

Filters, belts.

Everyone that saw the damage was surprised that we were able to get that much mud and debris into the bell housing. I see videos of Roxors in deep flowing water, crawling over huge rocks, and they look fairly indestructible. They are not. I'm going to avoid taking it in deep anything if I can help it. I'm afraid it's only going to get harder to get it fixed. Hope someone finds this helpful.